On the fourth day, we visited NASA Ames and got to not only see a smaller wind tunnel and water tank but we also walked into both the 1st and 2nd largest wind tunnels in the world! My uncle, Dr. Farid Haddad, and his colleague, Dr. Rob Fong, kindly led a 4-h tour of the facilities and answered many of our questions.

Our first stop was the Fluid Mechanics Lab (FML) where Rob works. Two interns showed us around and explained to us the work that they do there. Their job is to run small scale wind tunnel and water tests to determine how those models will perform in flight. In their lab, they have a 4 foot by 4 foot test section in the wind tunnel in which they can place models for testing.

A space shuttle model in the water tank. Green fluorescent dye is used to demonstrate flow over the model.

My uncle explained to us the seemingly complex nature of a wind tunnel in simple terms. On one end, a fan generates the wind which then travels to a diffuser board to guarantee that the wind hits the object directly, not in a vortex. The object that is in the test section is then hit with the wind, where it is possible for them to take both quantitative and qualitative measurements.

EDI Fellows below one of the test areas (circular)

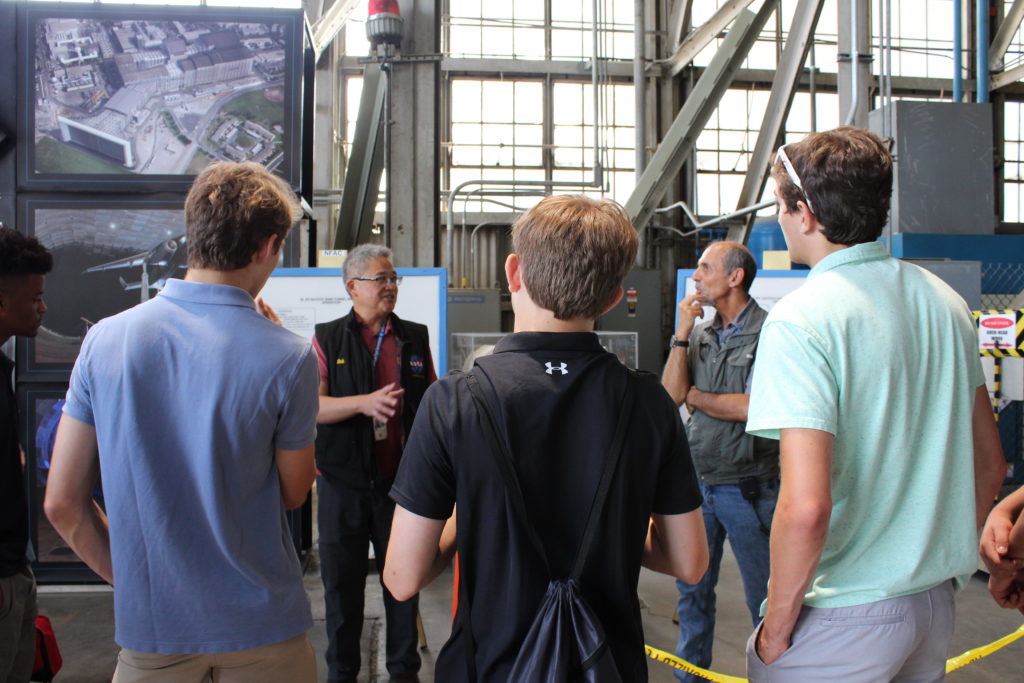

Dr. Rob Fong explaining the design of the wind tunnels

The EDI Fellows in one of the test areas (linear).

We then traveled to the two larger wind tunnels, the 80×120 and 40×80. Rob explained to us how NASA engineers built the 80×120 and then expanded the facilities to include a 40×80 wind tunnel test area. A complex set of door-like veins close off certain sections that switch the flow of the wind for either a circular or linear flow.

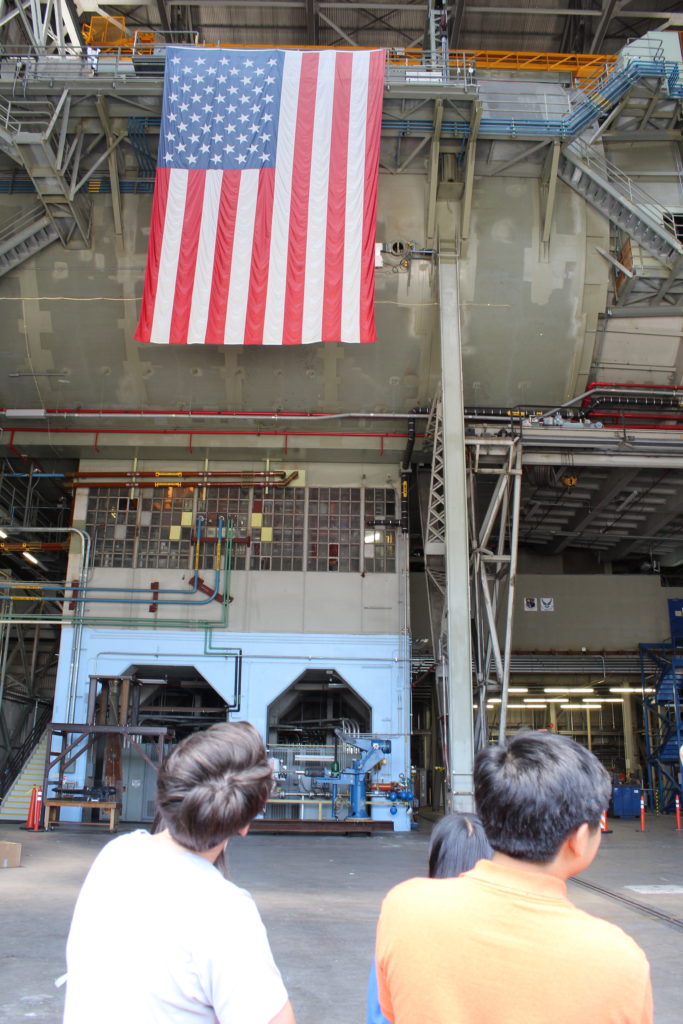

From there, we walked in the wind tunnel! We started out in the 80×120 test section as my uncle explained how the test model is fixed and brought into the test area. We walked all the way down to the bottom of the air intake area and learned about different properties such as the sound proofing of the test section so that engineers can reduce the sound of helicopter and supersonic aircraft.

Crane to put in the models into the test area

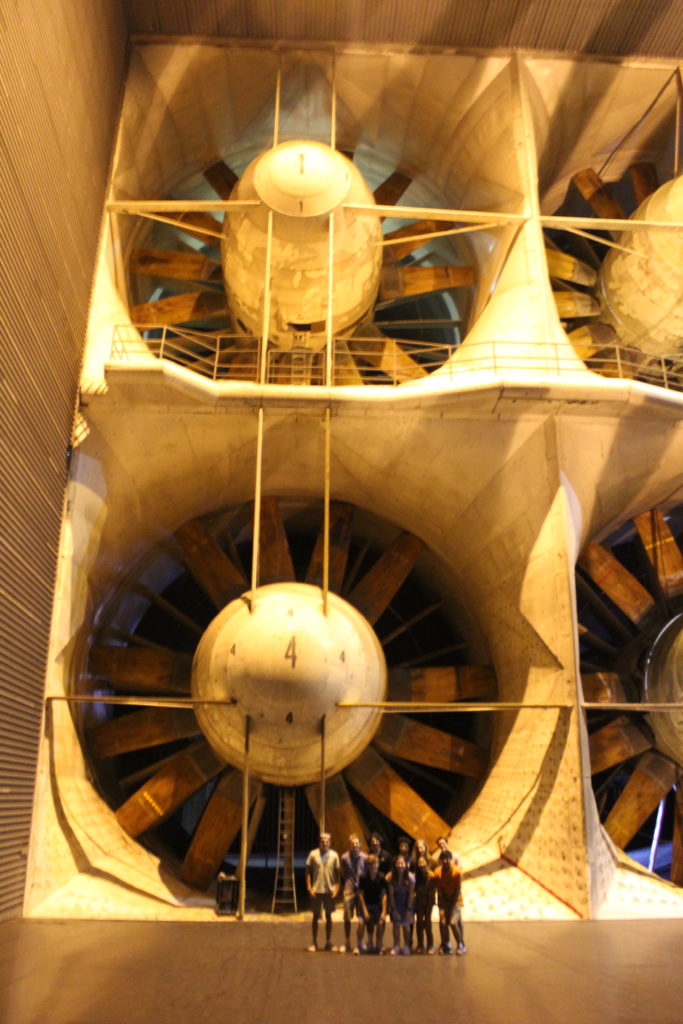

The EDI Fellows in front of two of the six turbines that draw in air for the NASA Ames Wind Tunnel

Turbines for Wind Tunnel. The slats help to create an unidirectional flow of air.

Dr. Farid Haddad shows the EDI Fellows how to move the door-like veins to change the type of wind flowing in the wind tunnel (circular or linear)

We then walked through a set of the door-like veins into where engineers control the air flow to the two test areas and into the massive turbines that draw in the outside air. The wooden blades were incredibly large about 3 humans tall. Rob explained that they still use wood because it is the easiest to fix and most reliable, although updating the wooden blades is highly debated among the scientific community of the Ames Wind Tunnel.

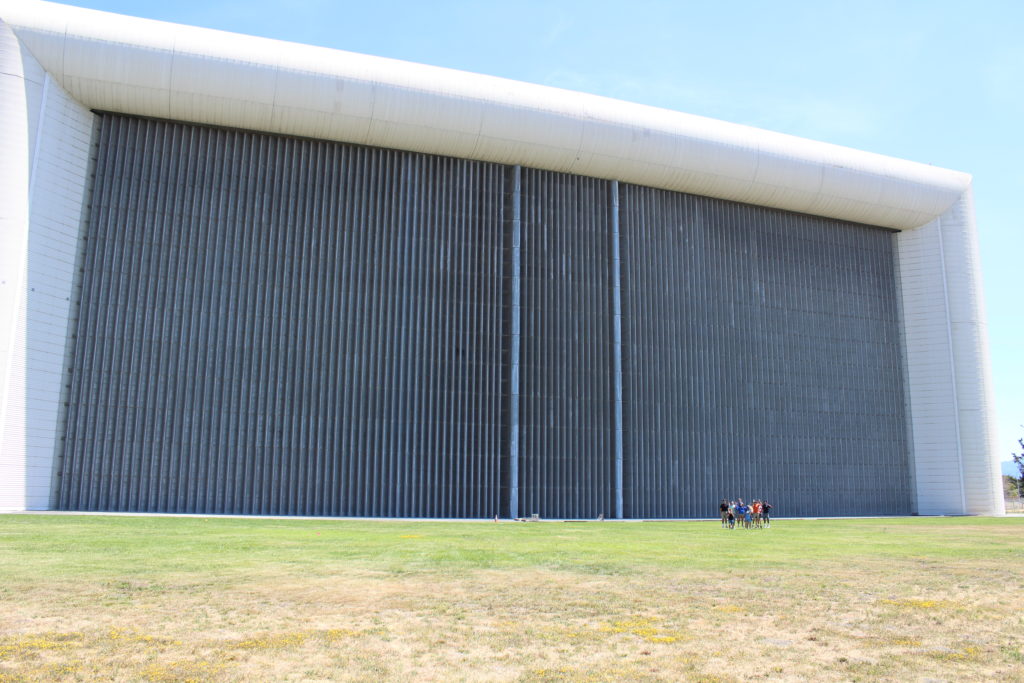

EDI Fellows jumping together in front of the NASA Ames Wind Tunnel

The EDI Fellows with Dr. Rob Fong (left) and Dr. Farid Haddad (right)

Last stop was the outside of the 80×120 wind tunnel intake, where we could view the ongoing construction of the Google’s new main campus. We took some photos outside and then it was time to head off to the escape room.

Post by Sarah Haugh EDI’20